I tend to come across many old turntables. A lot of the time I see them in the corner of somebody's basement when I am crate digging, or I'll find them cheap on kijiji, or even people who know I am into vinyl just give them to me.

Many times these turntables need little to no repair to have them up and running. Sometimes they need more. At first I would change the belt, put a new needle on it and hope for the best. However, if this didn't get the table I would usually just assume they are junk and throw them out in the shed thinking maybe I will use them for parts someday.

As my shed started to slowly fill up with these “dead tables” I started to feel a bit sad that these machines I love so much will never get to spin tunes again (corny I know). So I started researching more and more on how to repair these and decided to try to revive a few of them.

Well after many hours of reading and plenty of trial and error, I’ve actually been getting some decent results.

Sometimes it is a mechanical problem under the turntable that just needs adjustment, which I enjoy figuring out. What used to deem them as non-repairable in my eyes was when it turned out to be a circuit board that used to be the problem. Recently however, I bought a soldering gun and started experimenting fixing these boards and have been getting great results. This is turning into a pretty fun hobby. So I figured I would start sharing some of these projects here on Maritime Vinyl and I will call this the “Back from the Dead Turntables” feature of my site.

I hope you enjoy.

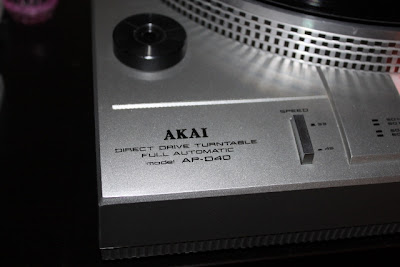

A few weeks ago I saved an Akai AP-D40 turntable from the dumpster. The owner was nice enough to ask if I would like to have it, if not to the garbage it went. So before I forget, thanks!

So this table was missing a stylus, which is a simple fix. I had a few

kicking around so I put one on it for the time being. However, this stylus is

temporary as I ordered the original one for the table on eBay and am waiting

for it to arrive.

The other problem with this table was a speed issue. You could just not set the pitch to get it at the correct speed. This is a direct drive turntable so it wasn’t a stretched belt which is often the case.

There is a place to adjust the speed for this turntable underneath when you remove the bottom but it would just not adjust correctly. I did a little research and some people who had the same problem said that they had to replace the capacitors on the circuit board. So I bought a soldering gun and ordered the correct capacitors online. This was my first soldering experience and it was nowhere near as difficult as I thought it would be.

I decided to replace all of the capacitors on this circuit board. So after I finished soldering and plugged it in, to my surprise, the speed adjustment now works perfectly!

The last problem I noticed on this table was that the automatic start and finish feature was not working. This was just caused by some old dried up grease. I just added some sewing machine oil to the grease and worked the parts and it now works perfectly. I was pretty proud of myself with this fix. So for less than $30 in parts (including the original stylus) and some patience, I now have a perfectly working Akai AP-D40.

Enjoy this video clip showing it coming back to life.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Thanks for this post. I just picked one of these up on kijiji for $35. Has a RS-90 stylus on it and everything seems to be working fine.

ReplyDeleteAppreciate any tips on a basic clean up as I have never even opened a TT before.